1100 Aluminum I-beam

Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance;

After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained.

Category:

Aluminum Section Steel

1100 Aluminum I-beam

About the aluminum

1100 aluminum alloy is 99.0% ordinary industrial pure aluminum. Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance; After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained. 1100 aluminum alloy is formed by adding a small amount of copper element in pure aluminum, with excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. Widely used in products requiring good formability and high corrosion resistance, but not high strength requirements.

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

PRODUCT

| Standard: | ASTM |

| Application: | steel structure,bridging,etc |

| Flange Thickness: | 8mm - 64mm,as required |

| Web Thickness: | 6mm-16mm,as required |

| Processing Service: | Bending, Welding, Decoiling, Punching, Cutting |

| Invoicing: | by theoretical weight |

| Delivery Term: | 7-10days |

| Thickness: | 8-64mm,as required, 8-64mm,as required |

| Length: | 6-12m,as required |

| Flange Width: | 100-300mm,as required |

| Web Width: | 96mm - 1056mm,as required |

| Tolerance: | ±1% |

| Delivery Time: | within 7 days |

| Shape: | I |

| Usage: | steel structure,bridging,etc |

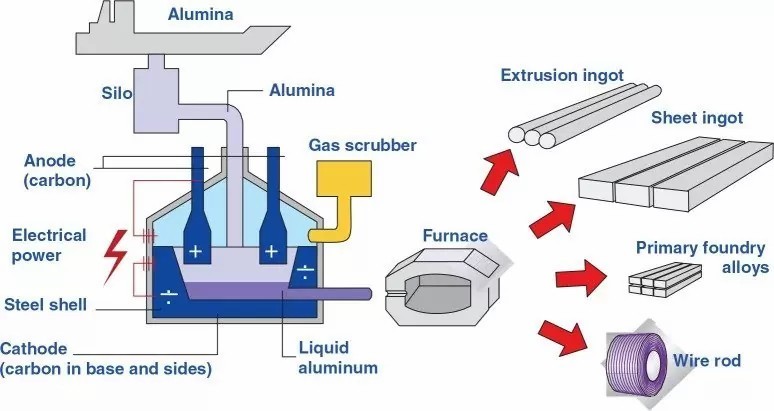

Aluminum Production Process

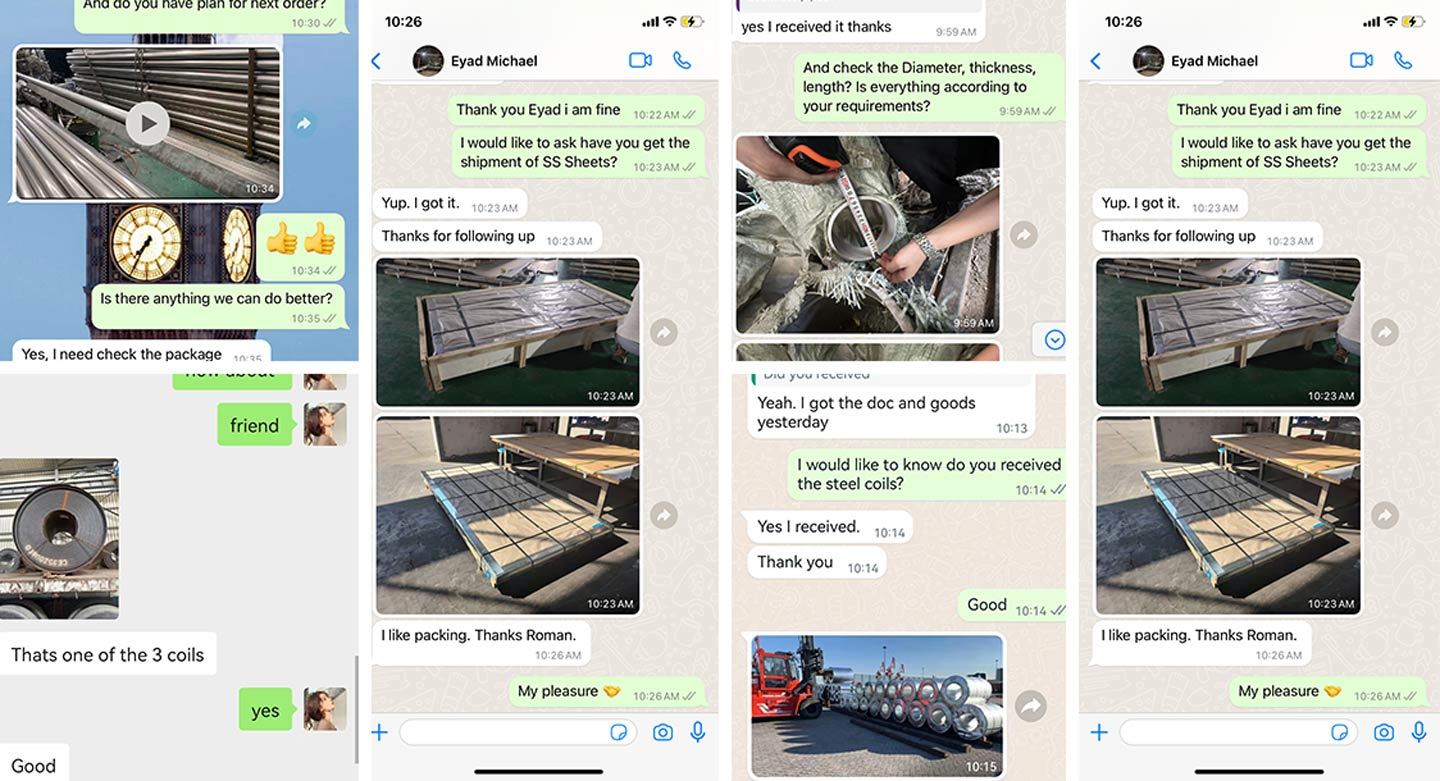

Packing and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

Production Process

FACTORY

Our steel group has the capacity to support 17.5 million tons of iron, steel and materials, and its overall equipment level has reached the world's first-class level, forming a production pattern of four high-quality lines of "plates, tubes, rails and lines".

Testing Equipment

Our steel group has the capacity to support 17.5 million tons of iron, steel and materials, and its overall equipment level has reached the world's first-class level, forming a production pattern of four high-quality lines of "plates, tubes, rails and lines"

CUSTOMER VISIT

It has scale advantages, resource advantages, integration advantages, technology research and development advantages, capital operation advantages, and has a complete pre-sales, sales and after-sales service system. We continue to innovate and seek transformation, and are willing to provide better services to customers around the world.

It has two world-leading large-scale universal steel rolling production lines and a waste heat quenching production line with a production capacity of 2.1 million tons. It is the high-speed rail production base with the highest equipment level and the largest capacity in the world. In terms of wire rod, it has 5 production lines including wire rods and strip steel, with a production capacity of 2.1 million tons. 2.25 million tons.

APPLICATION

The products are widely used in water conservancy projects, military equipment, construction industry, aerospace, automobiles, home appliances and other fields.

RELATED PRODUCTS