X42 Carbon steel pipe

Category:

Carbon steel pipe

X42 Carbon steel pipe

X42 pipeline pipe is the pipeline pipe with steel grade of X42. The pipeline pipe is used to transport the oil, steam and water pumped out of the ground to the oil and natural gas industrial enterprises through the pipeline pipe. Pipeline pipe includes seamless pipe and welded steel pipe, with flat end, threaded end and socket end at the pipe end; The connection methods are welding, coupling connection, socket connection, etc.

The steel grade includes X42-70, and the varieties include onshore pipeline pipe and submarine pipeline pipe. At present, the production of pipeline pipe adopts the micro alloying heating treatment process, and the production cost of stainless steel seamless pipe is significantly higher than that of welded pipe. With the improvement of steel grade, such as the limit of carbon equivalent for pipeline pipe with steel grade above X80, the conventional process of seamless pipe is difficult to meet the user's requirements; At present, each 12Cr1moV alloy pipe manufacturer is carrying out scientific research work to improve the corrosion resistance of its pipeline pipes and stabilize the service performance in low temperature and high temperature environments.

|

Item |

X42 Carbon Steel Pipe |

|

Length |

3-12M or as required |

| Outer diameter | 10mm-426mm |

| Wall thickness | 1-100mm |

|

Standard |

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

|

Technique |

Hot rolled/cold rolled |

|

Surface Treatment |

Black/Peeling/Polishing/Machined |

|

Thickness tolerance |

Control with in the standard, OD:+/-1%, WT:+/-5% |

|

Material |

X42 |

|

Coatings |

Standard export packing |

|

Export packing |

Waterproof paper, and steel strip packed. |

Products Display

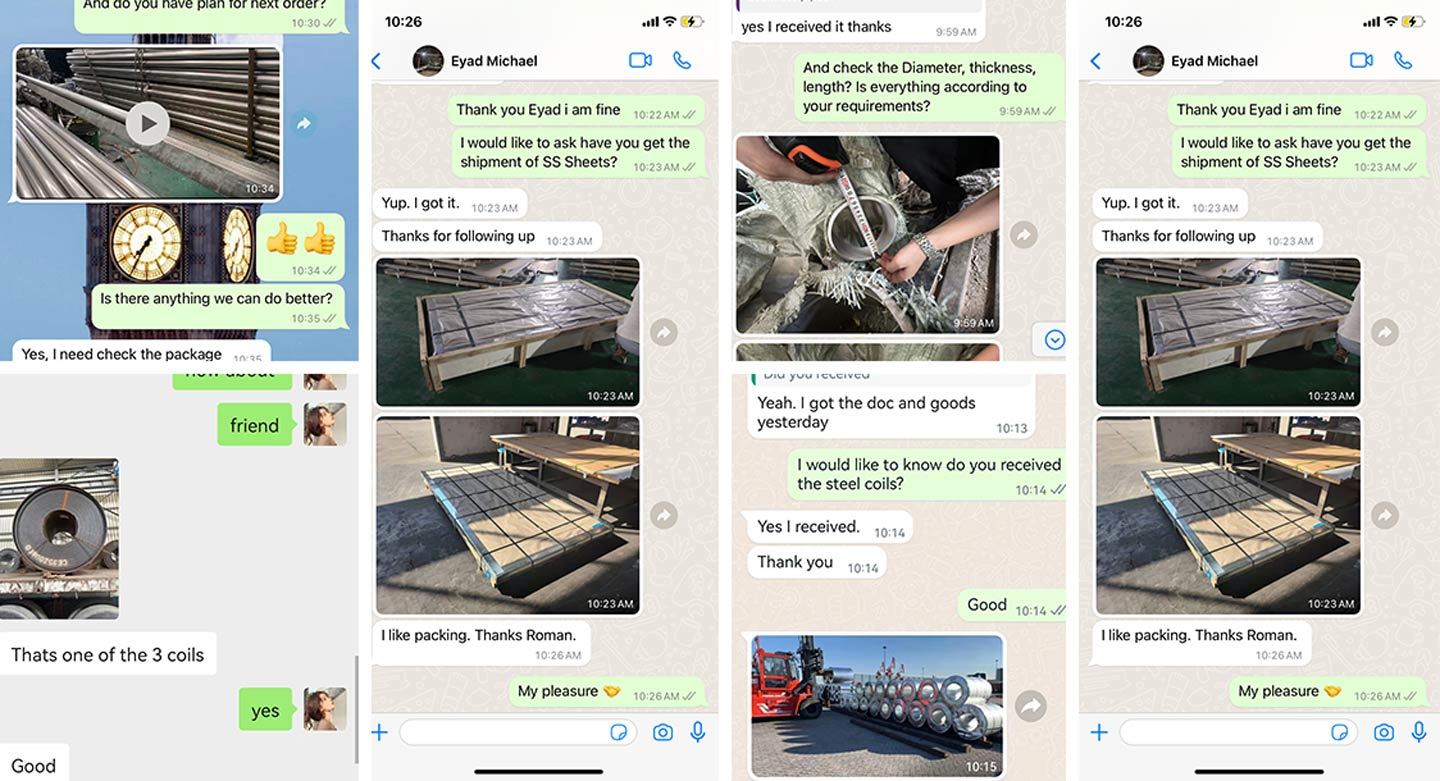

Packing and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

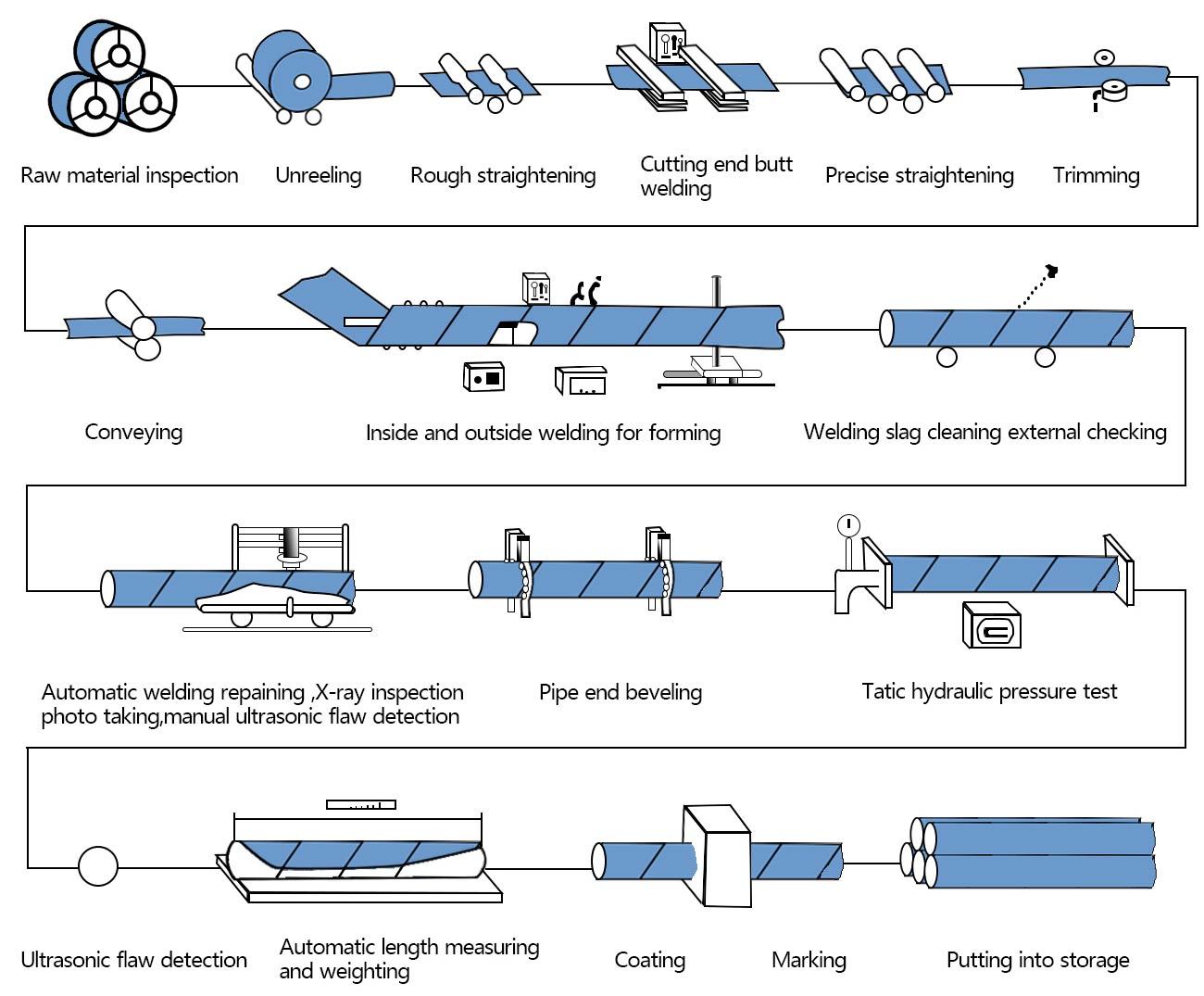

Production Process

FACTORY

Our steel group has the capacity to support 17.5 million tons of iron, steel and materials, and its overall equipment level has reached the world's first-class level, forming a production pattern of four high-quality lines of "plates, tubes, rails and lines".

Testing Equipment

Our steel group has the capacity to support 17.5 million tons of iron, steel and materials, and its overall equipment level has reached the world's first-class level, forming a production pattern of four high-quality lines of "plates, tubes, rails and lines"

CUSTOMER VISIT

It has scale advantages, resource advantages, integration advantages, technology research and development advantages, capital operation advantages, and has a complete pre-sales, sales and after-sales service system. We continue to innovate and seek transformation, and are willing to provide better services to customers around the world.

It has two world-leading large-scale universal steel rolling production lines and a waste heat quenching production line with a production capacity of 2.1 million tons. It is the high-speed rail production base with the highest equipment level and the largest capacity in the world. In terms of wire rod, it has 5 production lines including wire rods and strip steel, with a production capacity of 2.1 million tons. 2.25 million tons.

APPLICATION

The products are widely used in water conservancy projects, military equipment, construction industry, aerospace, automobiles, home appliances and other fields.

RELATED PRODUCTS