Aluminum Coil Tube

Temper: O and H14

length: 10ft,20ft,25ft,20ft,50ft etc

max working pressure:4.0Mpa

Processing:Hot extruded

Category:

Aluminum Coil Tube

Aluminum Coil Tube

Product introductionProducts Details

We are a manufacturer of Aluminum Coil Tubing Fuel Line 1/4,3/8,1/2,5/8 and 3/4

Widely used in the automotive and air conditioning industry as important HVAC parts.

Features:

Material alloy grade:1050.1060,1070

Temper: O and H14

Thin wall aluminum tubing

length: 10ft,20ft,25ft,20ft,50ft etc

max working pressure:4.0Mpa

Technical parameter:

Processing:Hot extruded

Pipe Tensible strength: 68-80Mpa

Tube Elongation: 30-40%

Bursting pressure > 1800 PSI

Bending at 1800 by 25mm bending radius: no visible crack.

Surface quality: smooth, no crack

Filling with Ni gas (>1.00Mpa), keep the pressure for at least 30 minutes,

Checking the pressure gauge with decreasing or not. No leakage is accepted.

Keep pressure in store about 24 hours before delivery

Bending testing:

Bending at 1800 by a 25mm bending radius, there is no visible crack.

Flattening testing:

Pressing tube to be flat (inner wall distance same as wall thickness), no visible crack to be found.

Cleaning test:

Clean the inner wall surface, without any pollution found, total impurity content remained 5~60mg/ m2

Technical data

Chemical Composition:

Various alloy grade aluminum tubing for sale

| 1050 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| 1060 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| 1070 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

Processing technology

1070 alloy aluminum tube is called a hot extruded aluminum tube.

Raw material 1070 aluminum wire rod size 9.5mm, feeding in the hot extruded machinery.

Extrusion model and temperature higher 570 °C aluminum half nearly melting

Aluminum tubing comes through a cold pure water tank to lower surface temperature.

Application:

Refrigerant tube in the HVAC industry

Air conditioner pipe for mini split line set

Automotive repair as fuel lines

Evaporator and condenser pipes

Gas stove connecting pipes

warranty

As one of the top aluminum tube suppliers, we have strict production management and quality control

NO leakage before delivery

Rohs certification environmentally

5 years of quality promise as HVAC parts.

Packing and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

Production Process

FACTORY

Our steel group has the capacity to support 17.5 million tons of iron, steel and materials, and its overall equipment level has reached the world's first-class level, forming a production pattern of four high-quality lines of "plates, tubes, rails and lines".

Testing Equipment

Our steel group has the capacity to support 17.5 million tons of iron, steel and materials, and its overall equipment level has reached the world's first-class level, forming a production pattern of four high-quality lines of "plates, tubes, rails and lines"

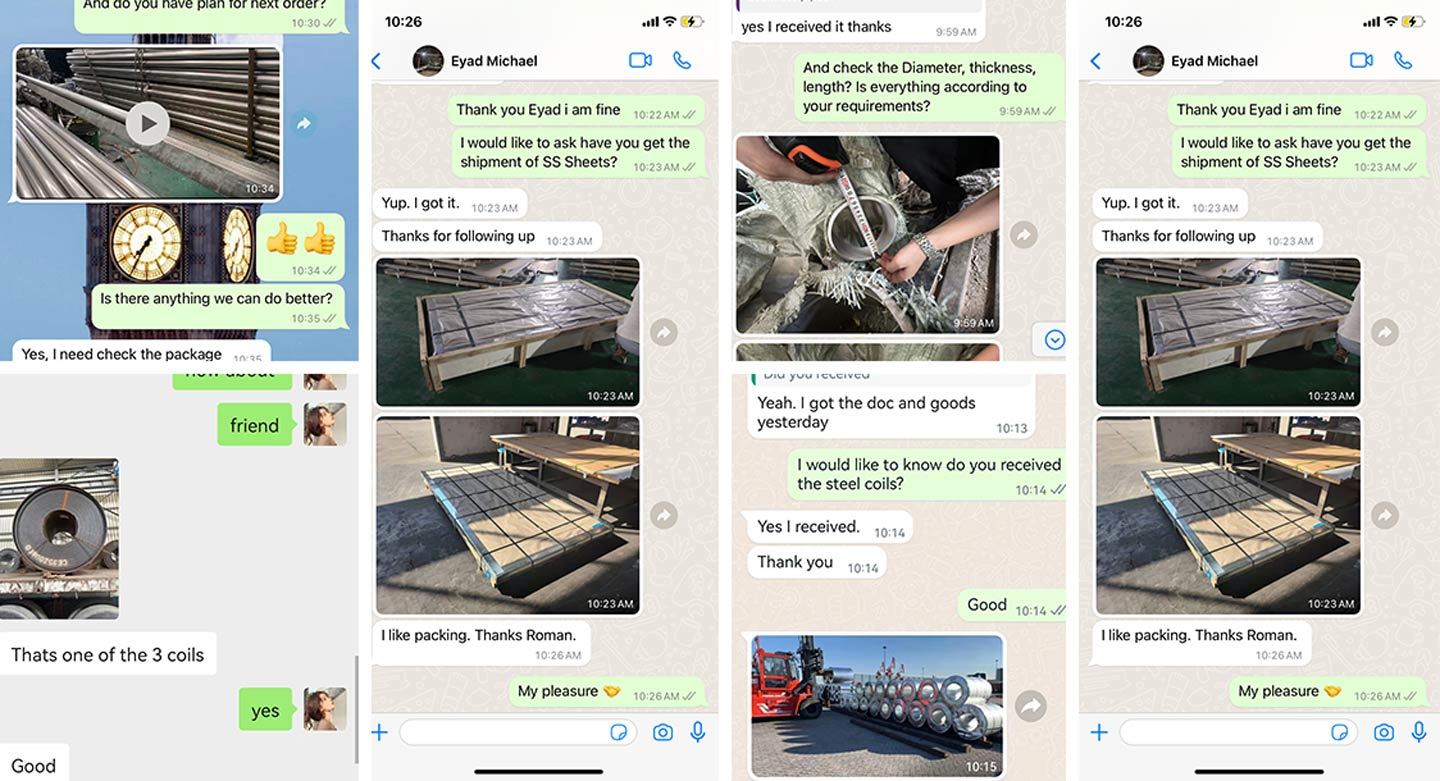

CUSTOMER VISIT

It has scale advantages, resource advantages, integration advantages, technology research and development advantages, capital operation advantages, and has a complete pre-sales, sales and after-sales service system. We continue to innovate and seek transformation, and are willing to provide better services to customers around the world.

It has two world-leading large-scale universal steel rolling production lines and a waste heat quenching production line with a production capacity of 2.1 million tons. It is the high-speed rail production base with the highest equipment level and the largest capacity in the world. In terms of wire rod, it has 5 production lines including wire rods and strip steel, with a production capacity of 2.1 million tons. 2.25 million tons.

APPLICATION

The products are widely used in water conservancy projects, military equipment, construction industry, aerospace, automobiles, home appliances and other fields.

RELATED PRODUCTS